Magnets are an essential part of our lives, from the electronics that power our devices to the motors that drive our cars. Have you ever wondered, though, how permanent magnets are made? In this blog post, we’ll be exploring a new way to create these powerful magnets. We’ll cover everything from understanding the traditional manufacturing process to introducing a revolutionary new approach, giving you an in-depth look at permanent magnets. So, let’s get started and explore a new way to create permanent magnets.

What Is A Permanent Magnet?

Have you ever wondered what makes a permanent magnet so special? Well, it turns out that permanent magnets are incredibly powerful and versatile pieces of technology. They’re used in many different applications, from store shelves to medical devices. And thanks to new technology that uses electrically remanence magnets, they’re becoming even more important. Here’s a quick overview of what a permanent magnet is and how the new technology works.

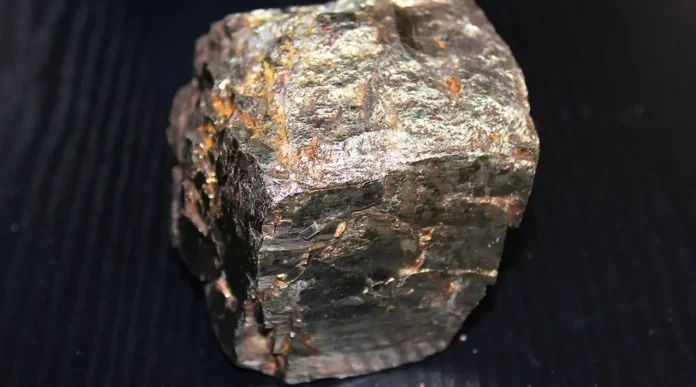

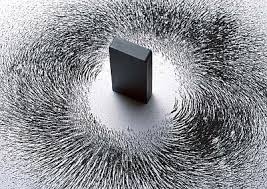

First, let’s define what a permanent magnet is. A permanent magnet is a material that contains magnetic fields inside it that are strong enough to remain after the original magnetic field has been removed. This is different from most other materials, which can only hold onto their magnetic fields for a short period of time before they lose them completely. Permanent magnets can keep their fields for much longer periods of time, making them perfect for use in various applications where durability and stability are key factors.

How the new technology works involves creating an electric field inside the permanent magnet while it’s still metalized (i.e., when it’s still made up of small pieces). This electric field causes the metal particles in the magnet to become charged up with energy – similar to how batteries work – and this energy remains even after the electric field is turned off. This means that permanent magnets can retain their properties even after they’ve been removed from their original location (or when they’ve been damaged).

This new type of Permanent Magnet technology has several advantages over traditional magnets:

– They’re much more durable: Traditional magnets can easily be damaged or destroyed by physical forces, but electrically remanence magnets can handle more abuse without breaking down. – They’re more efficient: Traditional magnets require a lot of energy to keep them functioning properly, but electrically remanence magnets require very little energy to maintain their magnetic properties. – They’re less expensive: Because traditional magnets are made from rare earth materials (which are often expensive), electrically remanence magnets tend to be cheaper than traditional ones overall. – They have potential applications in various industries: Permanent Magnet technology has potential applications in many different industries – including manufacturing, construction, automotive engineering, and more – because it offers unique benefits not found in other types of Magnets.

Understanding The Traditional Manufacturing Process Of Magnets

When it comes to magnets, there are two main methods that are used to produce them: traditional and new. The traditional process is slow and requires a lot of resources, while the new process is faster and uses less materials. Which method should you use? That’s the question we’ll be answering in this blog.

Before we get into the details, it’s important to understand what traditional magnet production entails. First, magnets are made from different types of materials that are heated until they reach a particular temperature. This temperature causes the material to transform into a permanent magnet. However, traditional magnet production has several disadvantages: it’s slow, difficult to control, and can be dangerous.

As for the new process, it uses less materials and is faster than the traditional process. However, there are several challenges posed by this method as well. For one, it’s difficult to produce high-quality magnets without causing any damage or defects in the material. Additionally, this method is not suitable for large-scale production because it requires precision and careful control over all aspects of the manufacturing process.

Introducing A New Way To Create Permanent Magnets

Permanent magnets are a crucial part of many industries, and their use is only going to increase in the future. Today, we’re going to be introducing you to a new process that can be used to create strong permanent magnets. This process is much faster and more efficient than traditional methods, making it a valuable option for businesses and consumers alike.

To begin, you will need some materials that you may already have on hand. You will need iron powder, copper powder, aluminum powder, salt water solution (5% or more), and an oven that reaches at least 350 degrees Fahrenheit. Next, follow these simple steps:

1) Preheat your oven to 350 degrees Fahrenheit

2) Mix the iron powder, copper powder, aluminum powder together in a bowl until they are fully combined

3) Pour the mixture into a small baking dish or casserole dish

4) Add salt water solution until it covers the magnet mixture completely

5) Place the dish in the oven and bake for approximately three hours or until the magnet mixture has turned into a hard black substance.

6) Remove from oven and let cool before using.

In Conclusion

Permanent magnets are essential components of modern technology, and their manufacturing process has a significant impact on the world. Traditional methods of creating permanent magnets can be expensive and time-consuming, but advances in technology have made it possible to introduce a new way to create permanent magnets quickly and efficiently. This new method promises to revolutionize the magnet production industry by providing a more reliable and cost-effective solution for producing magnets. We invite you to explore this new technology and see how it can help you or your business create stronger and more reliable permanent magnets faster than ever before.